Get ready for 2025 with our FREE ITP Checklists

Now is the perfect opportunity to get a jump start and gear up for projects that are starting in the new year. Grab one of our trade specific ITP Checklists to get started and see how easy it is to simplify the process. Complete the form below, select your Trade Type to receive your copy.

7 reasons construction teams should use Quality Assurance ITP's and Checklists

7 reasons why construction teams should use Quality Assurance ITP's and Checklists

1. Consistency; Checklists guarantee that each task is executed uniformly, minimising the chances of overlooked steps or mistakes.

2. Efficiency; They optimise processes, enabling workers to concentrate on their tasks without needing to recall every detail, thereby saving time and boosting productivity.

3. Safety; All construction has considerable safety hazards. Checklists help ensure adherence to all safety protocols, reducing the risk of accidents and injuries.

4. Quality Assurance; By using a checklist, contractors can confirm that all quality standards are satisfied before completing a project, resulting in greater customer satisfaction.

5. Training and Communication; Checklists can act as training aids for new employees and enhance communication among team members by providing a clear task outline.

6. Documentation; They offer a record of completed tasks, which can be valuable for future reference, compliance, and audits.

7. Problem Prevention; Checklists can help detect potential issues before they escalate into major problems, allowing for proactive solutions.

Why should you use an ITP Checklist if your an Electrical Contractor?

If you’re an Electrical Contractor, you sign-off and verify your own quality! It's particularly important to Integrate checklists into your workflow, checking as you go will greatly improve the reliability and quality of your work!

.png)

Get your Electrical Switchboard Checklist now

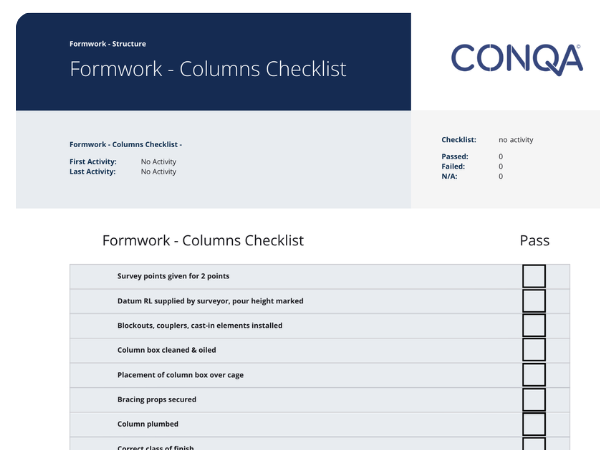

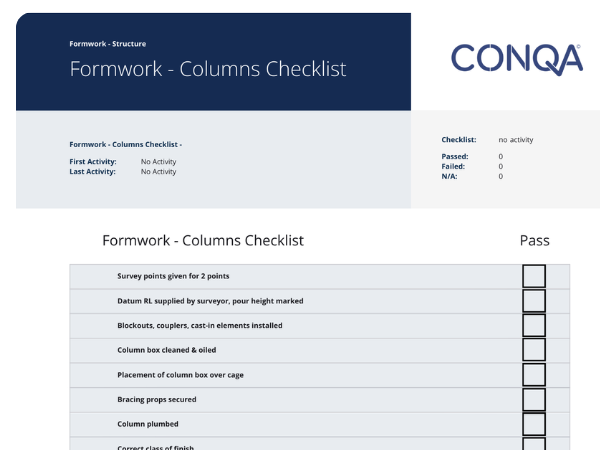

These same outcomes apply to ITP and Checklists for Formwork

CONQAs - Formwork: Columns (Foundations) ITP helps you ensure you have the essentials covered and helps you avoid any unnecessary risks.

Quality Assurance: This ITP checklist verifies that quality standards are upheld throughout foundation construction, helping ensure a solid and dependable structure.

Compliance: It supports compliance to building codes, regulations, and you can add your own project specifications, which is critical for securing approvals and engineer sign-off.

Risk Management: By thoroughly reviewing each component of the foundation work, potential issues can be caught and resolved early, lowering the risk of costly delays or structural failures.

Documentation: The checklist acts as a formal record of inspections and testing, providing transparency and accountability for everyone involved.

Communication: It fosters clear communication among team members, subcontractors, and clients, setting out the expectations and requirements for foundation work.

Consistency: Implementing a standardised Checklist creates consistency in inspection and testing, ensuring every foundation meets the same quality benchmarks.

Final Sign-off: An ITP Checklist aids in the final approval process, confirming that all necessary inspections and tests have been successfully completed before moving forward with construction.

Overall, an ITP Checklist is a crucial tool for managing the quality and integrity of foundation work in any construction project.

Get your Formwork Checklist now

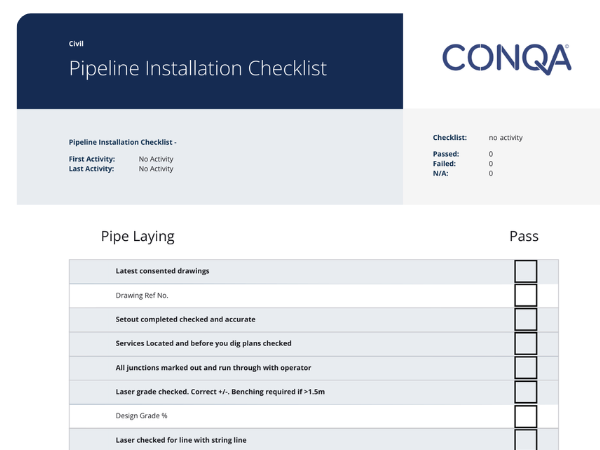

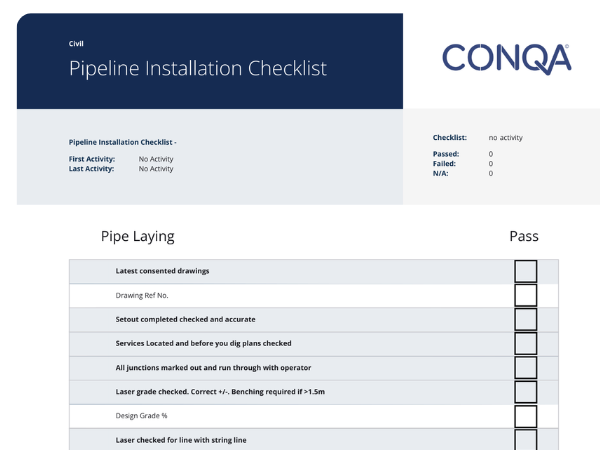

ITP Checklist for: Civil Pipeline Installation

Civil pipeline installation refers to the process of constructing and laying pipelines for various utilities, such as water, gas, oil, sewage, and telecommunications. This involves several key steps:

Planning and Design: Engineers assess the project requirements, including route selection, materials, and capacity. Environmental and regulatory considerations are also addressed.

Site Preparation: The installation area is cleared, and necessary permits are obtained. This may involve excavation or grading of the land.

Trenching: A trench is dug to the required depth and width to accommodate the pipeline. The trench must be stable and safe for workers.

Pipe Installation: Pipes are laid in the trench, often using specialised machinery. Connections between sections are secured, and fittings may be added as needed.

Backfilling: Once the pipes are in place, the trench is backfilled with soil. This is done carefully to avoid damaging the pipes.

Testing: After installation, the pipeline is tested for leaks and integrity, often using pressure tests or other inspection methods.

Restoration: The installation site is restored to its original condition, which may include replanting vegetation or repaving surfaces.

Monitoring and Maintenance: Once operational, pipelines require ongoing monitoring and maintenance to ensure they function correctly and safely.

Civil pipeline installation is critical for infrastructure development, ensuring that essential services are delivered efficiently and reliably.

Get your Civil Pipeline Installation Checklist now

ITP Checklist for: Formwork - Structure Formwork - Columns Checklist is built to help main contractors and speciality contractors with:

Quality Control: They help ensure that formwork is built and installed to the required specifications, resulting in high-quality concrete structures.

Compliance: ITP checklists ensure adherence to industry standards, building codes, and project specifications, which is essential for obtaining approvals and permits.

Risk Mitigation: By systematically identifying and addressing potential issues, checklists reduce the risk of defects, delays, and costly rework.

Documentation: They provide a formal record of inspections and tests, enhancing transparency and accountability for all parties involved.

Communication: Checklists facilitate clear communication among team members, subcontractors, and clients regarding expectations and requirements.

Consistency: Standardized checklists promote consistent practices in inspections and testing, ensuring that all formwork meets the same quality criteria.

Final Approval: They assist in the final sign-off process, confirming that all necessary checks have been completed before concrete placement.

Safety ITP checklists can include safety inspections, ensuring that formwork is secure and that workers are protected during construction.

Overall, ITP checklists for formwork are essential tools for maintaining quality, safety, and efficiency in construction projects.

Get your Structure Formwork Columns Checklist now

What our customers say

“We were pretty fortunate on this project to deliver on time (four months ahead of schedule) under budget and a really premium product.”

“With CONQA I'm saving two hours a day on ITP work.”

“It's about having the documentation there when you need it, the proof is there forever.”

Try CONQA for FREE

Quality Management Software for Construction. Simple, real-time QA inspections and ITP tracking. Get started with; Checklists, Sign-offs, QA Reports, Variations and Progress tracking.