5 mistakes costing civil contractors time and money

In civil construction, quality assurance isn’t just about ticking boxes, it’s about protecting time, budgets, and reputations.

Here are five common mistakes we see across the industry, and how practical, process-focused fixes can make the difference.

.png)

1. Missing hold points

Every contractor knows the importance of critical hold and witness points, yet they’re still one of the most common sources of rework and delays. On complex jobs, hold points can be missed simply because the process for tracking them relies on memory, text messages, or inconsistent spreadsheets.

When inspection points slip through, downstream work may need to be redone, often at the your expense. The fix isn’t complicated: schedule hold points as part of your daily workflow and use clear, accessible tracking tools so no critical check gets overlooked.

2. Incomplete or inconsistent inspections

Inspections are only as reliable as the data captured. When teams use a mix of paper forms, photos on phones, and manual sign-offs, information is easily lost or misinterpreted. Even small gaps, like a missing photo, unchecked box, or illegible note, can snowball into disputes or delays during closeout.

The best teams treat consistency as part of quality. Standardising inspection templates ensures everyone captures the same evidence in the same way, whether they’re in the field or the office.

"If you’ve got no photographic evidence of what you’ve done, it becomes incredibly hard to actually prove what you’re charging for is bona fide and valid"

Ken Pridham, Commercial Director, STÄRKE

3. Treating QA as a post-work activity

One of the biggest cultural pitfalls is viewing QA as something that happens after the work: a reporting task, rather than an active part of construction. This mindset means issues are often discovered only when documentation is being compiled, long after the opportunity to fix them easily.

Bringing QA forward into daily site routines changes the dynamic. When foremen, engineers, and subcontractors see quality checks as part of doing the work, not documenting it, problems are caught early, saving hours later.

4. Creating admin bottlenecks that delay closeout

A common frustration in project reviews is hearing, “the work’s done, we’re just waiting on paperwork.” Manual QA systems are slow to update and harder to coordinate across teams, meaning documentation lags behind progress on site. Those lags have real costs: milestone payments get delayed, engineers spend hours chasing updates, and project tails drag on longer than they should.

Even small efficiency gains make a difference. Automating submission and approval steps, or giving managers real-time visibility into inspection progress, keeps QA closeouts aligned with construction.

"These regularly updated records of QA means there are better lines of communication among all parties which helps to build trust, mitigate any long-term issues or mistakes and saves everyone money in the long term."

Ben Waterhouse, Renewals Manager, Higgins

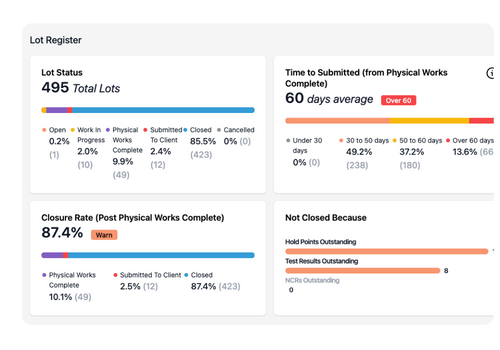

5. Not learning from QA data

Most QA data is collected for compliance, then forgotten once the report is signed off. That’s a missed opportunity. Over time, QA records reveal valuable insights, like which subcontractors deliver first-time quality, which work types drive the most NCRs, where rework keeps recurring.

Analysing that data, even at a basic level, helps contractors refine processes, reduce risk, and forecast labour more accurately. QA shouldn’t just record the past; it should inform better decisions on future jobs.

Build better QA habits

The goal isn't to increase the burden of admin and compliance, it's to build a QA process that works in the background, supporting crews and engineers rather than slowing them down. By tightening up your inspections, embedding QA earlier in the workflow, and learning from the data you already collect, you can reclaim hours each week and reduce risk across every project.

Quality assurance done right isn’t a cost. It’s a framework for saving time, protecting margins, and proving the quality of your work.

"With the help of CONQA, we can reduce manual paperwork, increase productivity and gain real-time insights throughout the build process."

Ajith Kulappurath, Regional Quality Manager, Fulton Hogan

Quality Management software for contractors

Let CONQA do the heavy lifting for you by making it quick and easy to streamline and digitise your QA. Keep all stakeholders updated with progressive QA to build quick and comprehensive project handovers.