From Reactive to Predictive

The Future of Maintenance QA

Most maintenance teams live in a reactive world.

A defect appears, someone logs it, and a crew is sent to fix it. It’s an endless cycle of urgent work orders, phone calls from the council, pressure to respond quickly, and the constant juggle of resource and budget.

For many contractors, this isn’t a failure of process; it’s simply the nature of maintenance. Ageing infrastructure, unpredictable conditions and tight SLAs mean teams are always responding to what’s right in front of them. But it also means budgets are stretched, crews are firefighting, and councils struggle to justify long-term investment because they don’t have a clear picture of what’s happening across the network.

The problem with reactive QA

Traditional QA in maintenance is inconsistent and fragmented. Photos are saved to phones or buried in emails. Evidence is uploaded days later, or not at all. Sign-offs happen, but they’re not structured or standardised enough to be useful beyond proving basic compliance.

- Evidence is collected after work is already complete

- Issues are only discovered when they become failures

- Councils can’t see patterns, they can only see what’s already gone wrong

- Contractors can’t forecast, because the data is limited to the latest defect

It’s compliance, not insight. And because it sits on the back end of the process, often in hard copies or uploaded in batches, it has no ability to shape future decisions.

What predictive QA actually means

Predictive QA flips the model. Instead of recording what has already happened, QA becomes the lens through which contractors and councils understand what’s likely to happen next.

.png?width=600&height=360&name=MacBook%20Pro%2015_%20-%204th%20Gen.psd%20(4).png)

- where defects tend to appear

- which assets degrade fastest

- seasonal or environmental trends

- which crews or methods produce better outcomes

- locations that repeatedly require rework

- areas where SLAs are at risk

This isn’t theoretical. Contractors who capture this data well can see early indicators of failure long before they appear in the defect backlog.

Predictive QA lets you intervene before the asset fails.

"If a job is done poorly, when it’s assessed, the company has to pay back a portion of the money due to the reduced life-span. This represents significant risk. If you perform well though, you get additional years on the contract, and the probability of you re-tendering is quite high."

Ben Waterhouse, Renewals Manger, Higgins

How CONQA enables predictive maintenance QA

What makes predictive QA powerful is not just the data, but how fast teams can access and interpret it. This is where CONQA plays a critical role.

1. Structured QA at the point of work

Every lot captures the same information the same way, every time: photos, measurements, sign-offs, locations, crew details, materials, environmental notes. The data is standardised from day one, meaning it’s ready for analysis, not just for compliance.

2. Real-time dashboards to identify patterns early

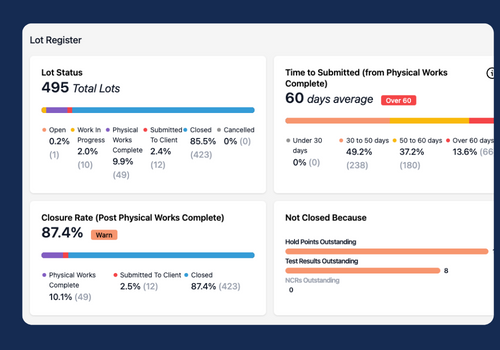

CONQA’s Lot Dashboard gives contractors and councils a running picture of what’s happening across the network. As soon as QA is submitted, it appears in live dashboards. This means:

- repeat issues surface immediately

- hotspots can be identified before they become budget blowouts

- foremen and supervisors don’t have to wait for end-of-month reporting

- operations managers can reprioritise crews based on emerging trends

3. Integration with asset management systems

Through APIs, QA data can flow into asset management platforms like RAMM, GIS tools, or council AMS systems.

This creates a single picture of asset health: work completed, underlying conditions, locations of recurring issues, and performance over time.

When QA data enriches asset management data, you get more than a record of completed tasks, you get insight into the long-term behaviour of assets. That’s the heart of QA data asset management.

4. Better visibility strengthens relationships

Increasing demand for evidence-backed reporting means contractors need clarity, not complexity.

Predictive QA strengthens that trust by giving clients visibility into not just what was done, but what’s coming.

Why predictive QA matters for maintenance contractors

The shift from reactive to predictive QA isn’t just about technology, it’s how you operate. It changes how you plan, allocate resource, and justify spend.

Predictive QA means fewer surprise failures. Crews can be scheduled proactively, addressing issues before they escalate. Budgets stretch further because the network is maintained earlier and more strategically. Clients see better value because they can point to clear, evidence-based decisions.

And most importantly, it reduces the cycle of firefighting. Contractors gain control over their pipeline instead of reacting to it.

The future of maintenance starts with how you capture QA

Predictive maintenance doesn’t demand new inspections or major workflow changes — it simply relies on QA that’s structured, live, and connected. When QA becomes usable data, planning improves, disputes fade, budgets stretch further, and SLAs become easier to meet. Small issues are caught early, long before they become costly failures.

Maintenance is shifting fast, and the contractors who embrace predictive QA now will set the standard for the next decade.

See how you can leverage your QA

Let’s help you get ahead of what’s coming, not just respond to it.

Book a demo to find out more!