Prevent backlogs: how smarter QA keeps infrastructure maintenance on schedule

In road maintenance, every delayed inspection creates a ripple effect. One late sign-off can stall an entire program, causing unfinished work, missed KPIs, and frustrated residents.

Why QA backlogs form in maintenance work

Quality assurance should be a seamless part of the delivery process, but in maintenance contracts, it often becomes a major bottleneck. The delays typically stem from operational friction, not a lack of effort. Common causes include the large geographic spread of sites, making it difficult for supervisors to get to every job promptly. This is compounded by a reliance on manual, paper-based inspection records, which are slow to fill out, easy to lose, and create a significant lag between on-site sign-off and office processing. Finally, a lack of real-time reporting to asset owners means issues aren't flagged until it's too late, turning minor issues into major delays.

The real impact of QA delays on maintenance programs

A small QA delay on a single task can create a snowball effect across an entire maintenance program. The most immediate impact is on the schedule, where tasks get rolled over from one week to the next, creating a backlog that can quickly become unmanageable. Disruption leads to an increased risk of rework, as fixing non-conformances becomes more complex once subsequent work has already begun. Ultimately, these internal challenges spill into the public domain. Delayed projects and extended road closures lead to a reduction in public trust, damaging the reputation of both the client and the contractor.

"Regularly updated records of QA means there are better lines of communication among all parties which helps to build trust, mitigate any long term issues or mistakes and saves everyone money in the long term"

Ben Waterhouse, Renewals Manager, Higgins

Best practices to keep your QA work to schedule

- Standardise with digital templates to ensure consistent data capture, leading to faster reviews and more reliable reporting.

- Go mobile-first for inspections to capture photo evidence on the spot, even without a network connection. This dramatically reduces paperwork and provides instant proof for faster sign-offs.

- Automate reporting with live data using an API to pull live QA data directly into business intelligence tools like Power BI, where you can build custom reports to analyse performance trends and track contract KPIs.

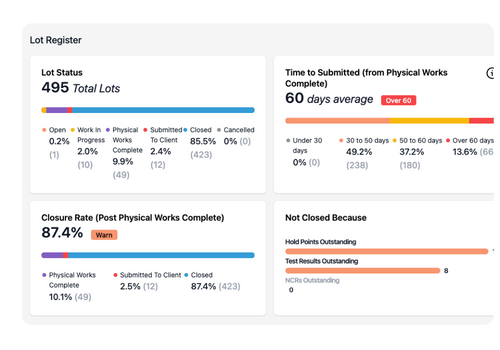

Case study: how Higgins uses CONQA to keep road maintenance on track

For a major contractor like Higgins, managing long-term Network Outcomes Contracts (NOCs) means overseeing hundreds of kilometres of highways. With multiple projects running at once, QA paperwork can quickly become a major source of delays.

According to Renewals Manager Ben Waterhouse, their Project Managers now need to be on-site regularly, but not "every second of the day." By implementing a digital QA system with CONQA, they empowered their PMs to manage QA remotely. Instead of spending their time chasing paper-based ITPs, they can now review progress across several sites from anywhere. This allows them to spend their valuable on-site time with project teams, not buried in administration, which is critical for keeping the wider maintenance program on schedule. Read the full case study here: Higgins builds a reputation of reliable quality

Ultimately, preventing maintenance backlogs comes down to closing the gap between work done in the field and the data in the office. By equipping your teams with the right digital tools, you can keep your program, and your reputation, on track.

Learn how a simple digital tool can keep your maintenance schedule on track. Book a quick demo with our team.